Loher Vatan Bilgisayar

Loher Vatan Bilgisayar

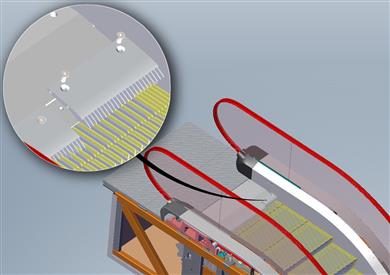

Loher Tarak Detayı

Loher Tarak Detayı

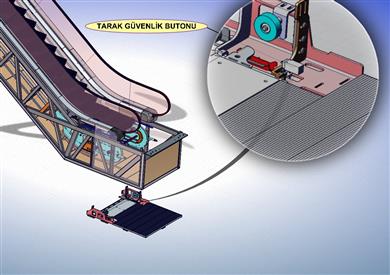

Loher Tarak Butonu

Loher Tarak Butonu

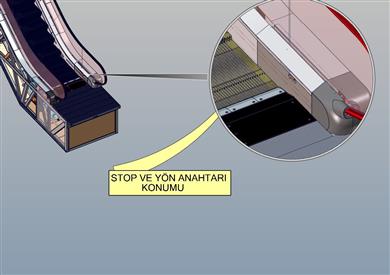

Loher Stop ve Yan Anahtarı

Loher Stop ve Yan Anahtarı

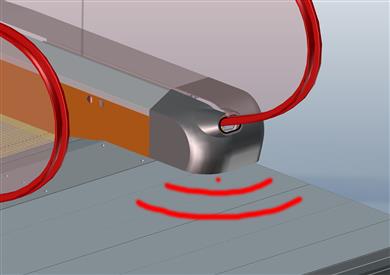

Loher Radar

Loher Radar

Loher Tahrik Sistemi

Loher Tahrik Sistemi

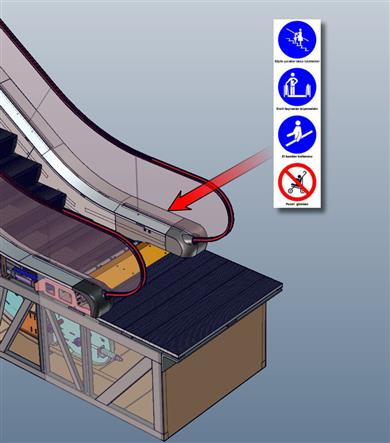

Loher Etiket Gösterim

Loher Etiket Gösterim

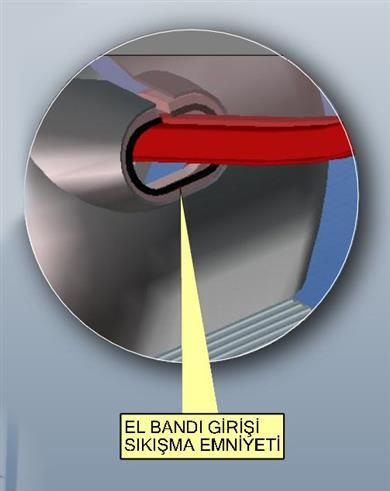

Loher El Bandı Sıkışma

Loher El Bandı Sıkışma

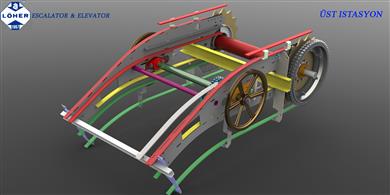

Loher Ust İstasyon

Loher Ust İstasyon

Loher Viyana C&A Mağazası

Loher Viyana C&A Mağazası

Löher Hatay Havaalanı

Löher Hatay Havaalanı

Loher Uturm Sanat Merkezi Dortmund

Loher Uturm Sanat Merkezi Dortmund

Loher Uturm Sanat Merkezi Dortmund

Loher Uturm Sanat Merkezi Dortmund

Löher Kabatepe Gösteri Merkezi Çanakkale

Löher Kabatepe Gösteri Merkezi Çanakkale

Löher İzmit

Löher İzmit

Löher Dış Ortam Yürüyen Merdiven

Löher Dış Ortam Yürüyen Merdiven

Löher Coton

Löher Coton

Löher CA İstanbul

Löher CA İstanbul

Löher CA İstanbul

Löher CA İstanbul

Loher Zara

Loher Zara

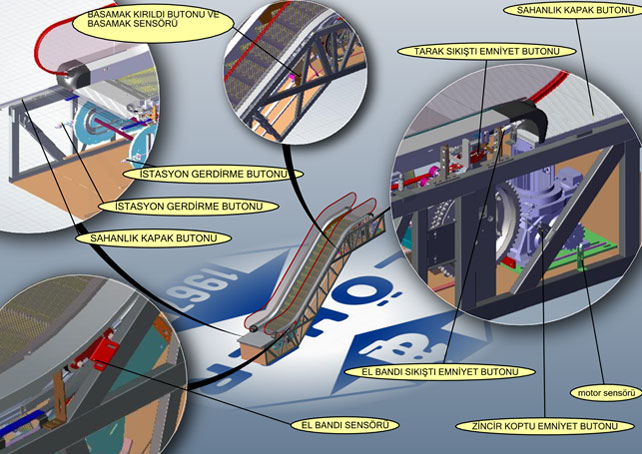

Standard designs are used, as well as special designs can be prepared according to customers’ requests.

The special design patterns which reduce the measurement errors and welding shrinks in process controls, error percentage is close to zero and this amazes the customers.

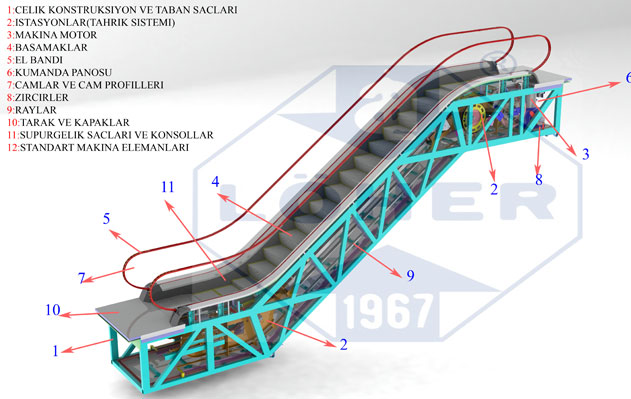

Upper and lower stations which are among the most important parts of the escalator are manufactured as standard in special patterns. All station rails used are made of cold drawn steel and their surfaces are cleaned for comfort. All materials in drive unit are chosen from certified and qualified steels. Also all steels are hardened against corrosion. In terms of lifetime, the chosen bearings are much superior than the other bearings and this provides the escalator smooth operation for long years.

The main fact in the designing process is to create the escalator which is the most appropriate one to the building structure, without compromising the standards. The most important point is the passenger safety. For that reason this is the first issue to be considered.

According to the data acquired as result of the first explorations, the carrying carcass of the escalator is designed in 3D. Later on, static and dynamic analyses are carried out by computer and the compatibility of the carcass is approved. If there is no problem at the end of the test, the other parts of the escalator are installed to the carcass. The total weight to the building of the escalator during its full capacity working process is calculated and reported to the project owner. The necessary controls in 3D design are carried out if an implementation out of the standards because of the building dimensions is seen. If necessary, the risk staff comes together and the risk analysis process is carried out. Thus, maximum safety and customer satisfaction is provided.

Following the customer approval, all the manufacturing designs and product receipts are forwarded to production department.

It is possible to add special fire systems required by fire regulations to the escalators installed in buildings such as shopping malls, hypermarkets. Their projects are prepared by professionals, installation of systems and their tests are realized by expert teams.

With owned vulcanization technology almost all kinds of handrail can be repaired or provided you a new one. In case of necessity, we try to fulfil the requests of our customers by assembling on-site service.

For the purpose of energy savings special motion sensors are fixed on the escalators. Because the sensors used work with radar logic it is not influenced by light reflections like photocell.

Exterior cover of escalators can be made of Alucobond Covering, Electrostatic Painting, Glass Covering and Stainless Steel Covering according to the customers’ request.

CONTROL PANELS OF THE ESCALATORS

The manufacturing of the control panel is to be carried out in the ideal way according to the customer demands and related standards.

In the escalator control panels, quality materials used are compatible with work intensity, made in Europe and providing maximum passenger safety. All the installation and wiring of the PLC controlled systems are carried out in the factory.

Siemens brand PLC systems are used in the escalator control panels are programmed by the engineers within the factory. The software can be designed according to the customers’ demand.

The control panels are rendered perfectly by the intermediate controls during the manufacturing process. After the final quality controls, the panels are ready to be installed.

The control panels with direct system and control all the mechanism are manufactured in two types as Star/Delta and with the variable frequency control systems. The variable frequency control systems make possible energy savings by changing the speed from high to fixed and low speed when there is no passenger.